In today’s fast-paced industrial landscape, optimizing productivity has become paramount for businesses striving to stay ahead of the competition. The advent of cutting-edge technologies has paved the way for innovative solutions that can significantly enhance efficiency and streamline operations. One such groundbreaking development is the revolutionary Zero-Point Mounting System.

A Quantum Leap in Precision Engineering

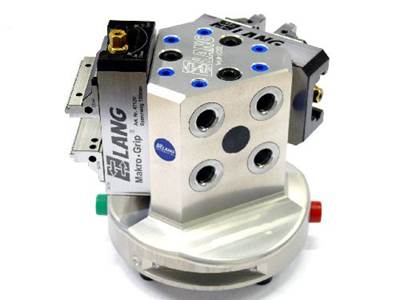

The Zero-Point Mounting System represents a paradigm shift in precision engineering, offering unparalleled accuracy and repeatability. This state-of-the-art system eliminates traditional setup times by providing an automated solution that securely holds workpieces during machining processes. By minimizing downtime associated with manual adjustments, this advanced technology enables manufacturers to maximize their production output.

Employing a meticulously designed modular interface, this system ensures seamless integration with various machine tools and fixtures. Its robust construction guarantees exceptional stability even under high loads, ensuring precise positioning throughout demanding manufacturing tasks. With its ability to swiftly exchange workpieces without compromising accuracy, the Zero-Point Mounting System empowers businesses to achieve unprecedented levels of efficiency.

Redefining Flexibility and Adaptability

Beyond its remarkable precision capabilities, the Zero-Point Mounting System offers unrivaled flexibility and adaptability in modern production environments. Its versatile design allows for effortless reconfiguration according to evolving requirements or changing product lines.

This ingenious system facilitates rapid changeovers between different setups while maintaining optimal alignment—a crucial advantage when dealing with diverse workpiece geometries or complex machining operations. By reducing setup times from hours to minutes, manufacturers can seamlessly transition between projects without sacrificing quality or productivity.

A Catalyst for Productivity Enhancement

The implementation of the Zero-Point Mounting System serves as a catalyst for productivity enhancement across industries worldwide. By minimizing human error and eliminating the need for manual adjustments, this cutting-edge technology significantly reduces setup times and increases machine utilization rates.

Moreover, its seamless integration with computer numerical control (CNC) systems enables real-time monitoring and data-driven decision-making. This invaluable insight empowers businesses to optimize their manufacturing processes further, identify bottlenecks, and implement targeted improvements that drive productivity gains.

Revolutionize Your Manufacturing Operations Today

In conclusion, the Zero-Point Mounting System represents a groundbreaking advancement in precision engineering that revolutionizes manufacturing operations. Its unrivaled accuracy, flexibility, and adaptability make it an indispensable tool for businesses seeking to enhance productivity while maintaining exceptional quality standards.

By embracing this cutting-edge technology, manufacturers can unlock new levels of efficiency and competitiveness in today’s dynamic industrial landscape. The Zero-Point Mounting System is not merely a solution; it is a transformative force that propels businesses towards unparalleled success.