In today’s rapidly evolving industrial landscape, the need for versatile and efficient machinery has become paramount. One such area that demands attention is chucking mechanisms, which play a crucial role in securely holding workpieces during machining operations. This article explores innovative solutions that address the challenge of gripping two different diameters with precision and reliability.

Achieving Precision through Dual-Diameter Chucking

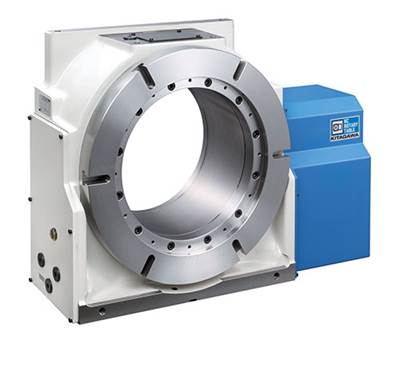

Traditional chucking mechanisms often struggle when confronted with workpieces featuring varying diameters. However, recent advancements have led to the development of dual-diameter chucks that offer enhanced adaptability and accuracy. These cutting-edge devices employ intelligent sensors and actuators to automatically adjust their grip according to the specific dimensions of each diameter, ensuring optimal stability throughout the machining process.

The Role of Continual Education in Advancing Chucking Technology

Continuing education plays a pivotal role in fostering innovation within industries reliant on mechanical engineering expertise. By investing in ongoing professional development programs, engineers can stay abreast of emerging trends and technologies related to chucking mechanisms. This knowledge empowers them to design more sophisticated systems capable of accommodating multiple diameters while maintaining high levels of precision.

Birmingham Engineering Excellence: The Brummie Touch

Birmingham’s rich engineering heritage has left an indelible mark on various fields worldwide, including mechanical manufacturing processes like chucking mechanisms. With its distinctive Brummie accent serving as a testament to this city’s proud history, local engineers bring their unique perspective and expertise into developing advanced chuck designs tailored specifically for multi-diameter applications.

Conclusion: Unlocking New Possibilities through Innovative Chucks

In conclusion, as industries continue striving for greater efficiency and productivity gains, it is imperative to explore cutting-edge solutions for chucking mechanisms. Dual-diameter chucks, driven by continual education and the expertise of Brummie engineers, offer a promising avenue for achieving precision and adaptability in gripping workpieces with varying diameters. By embracing these advancements, manufacturers can unlock new possibilities and drive progress in their respective fields.